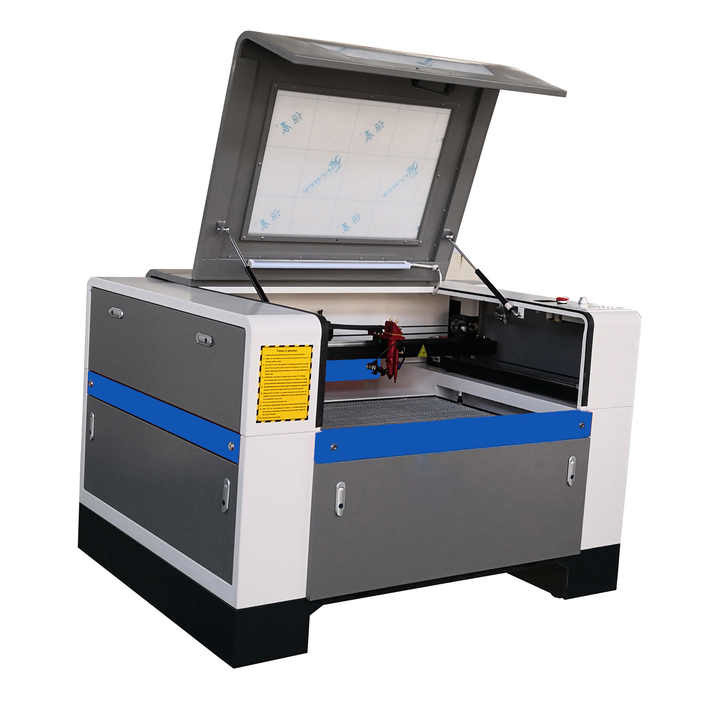

6090 1390 1610 60W 80W 100W Wood Printer Co2 Laser Engraving Machine

Product Descriptions:

Laser engraving machine is a technological equipment that uses laser to engrave materials that need to be engraved. Laser engraving machines are different from mechanical engraving machines and other traditional manual engraving methods. Mechanical engraving machines use CNC machinery, such as high-hardness diamond and other extremely hard materials, to engrave other things with lower hardness.

A laser engraving machine is also called a laser engraving machine. It includes a laser and a gas nozzle on its output light path. One end of the gas nozzle is a window, and the other end is a nozzle coaxial with the laser light path. The side of the gas nozzle is connected to a trachea, especially The trachea is connected to an air or oxygen source, the pressure of the air or oxygen source is 0.1 to 0.3MPa, and the inner wall of the nozzle is cylindrical, with a diameter of 1.2 to 3mm and a length of 1 ~8mm; the oxygen in the oxygen source accounts for 60% of its total volume, and a reflector is placed on the optical path between the laser and the gas nozzle. It can improve the efficiency of engraving, make the surface of the engraved area smooth and round, quickly reduce the temperature of the non-metallic material being engraved, and reduce the deformation and internal stress of the engraved object; it can be widely used for various The field of fine engraving on non-metallic materials.

| Mode |

MT-1390 |

| Work Area (mm) |

1300*900 |

| Laser Generator |

Water cooled Co2 glass sealed laser tube |

| Laser Power |

30W/150W(Optional) |

| Drive Motors |

Micro stepping stepper motor system |

| Control System |

64 Bit DSP |

| PC Interface |

USB 2.0 Port,USB Disk |

| Cutting Speed |

0-36000mm/min |

| Engraving Speed |

0-64000mm/min |

| Resolution Ratio |

<4000dp |

| Power Supply |

AC110V/220V-240V±10%,50HZ |

| Location Precision |

<0.05mm |

| Operating Temperature |

0°C-45℃ |

| Graphic Format Supported |

HPGL(PLT),JPGE,PCS,TGA,DST

DXP,DXF,DWG,CDR |

| Optional Engraving Device |

(cylinder)Dia(10~100)(50~300)mm |

| Dual Laser Head |

No |

| Gross Power |

<1250W |

| Engraving Parts Thickness (mm) |

0-140 |

| Weight (kg) |

580 |

| Warranty |

12 Months |

Applications on Shoe industry:

The advantage of laser processing is that it can quickly engrave and hollow out various patterns on the surface of various shoe upper materials. Since laser processing is a non-contact processing method, it will not cause any external deformation of the shoe upper. It also has many advantages such as high engraving precision, hollowing out without burrs, and can process any shape.

However, it is precisely because of the high-density energy characteristics of laser that when laser cutting or laser cutting shoe upper materials, especially light-colored materials (such as white, beige, etc.), or special materials (such as mirror materials, etc.), the upper The surface or inside of the product is prone to burning or yellowing.

In order to prevent this phenomenon from occurring, it is necessary to perform a certain protective treatment on the surface of the shoe upper during production and processing. Common methods include:

1. When applying the protective film, it must be flat and tight without any bubbles.

2. Soak some shoe uppers. This method is suitable for certain materials.

3. Adjust the laser processing parameters and use multiple times of small firepower.

Certificate

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!