High Efficient Safe Easy Maintenance Waste Breaker Shredder Machine For Recycling

Product Description:

The Shredder Machine for Recycling is a cutting-edge equipment that is designed to efficiently and safely shred waste materials for recycling purposes. This machine is not only efficient in its operation but also ensures the safety of the operators and the surrounding environment.

Product Features:

The machine features a robust and sturdy design that can withstand the wear and tear of continuous use. It is equipped with advanced shredding technology that can quickly and efficiently shred a wide range of waste materials, including plastic, paper, cardboard, and other recyclable materials.

The Waste Breaker Shredder Machine also offers easy maintenance, reducing downtime and simplifying the overall operation. It has a user-friendly interface that allows operators to easily monitor and control the machine's operations.

In addition, the machine is equipped with safety features that protect operators and prevent accidents from happening. It has an automatic shutdown mechanism that stops the machine in case of any malfunction or abnormal operation.

The Waste Breaker Shredder Machine for Recycling is an essential equipment for any recycling facility as it helps to efficiently process waste materials, reducing the environmental impact and turning waste into a valuable resource.

| Parameters |

Model OPS-400 |

| Motor |

4KW |

| Gearbox |

JL3#-12 |

| Input rotation |

12rpm |

| Input torque |

2919Nm |

| Shaft |

Φ60 |

| Blade |

Φ180*15,9CrSi |

| Blade nos |

26pcs |

| Inlet size |

600*500*300mm |

| Outlet width |

420mm |

| Outlet height to floor |

200mm |

| Overall size |

1160*600*1450mm |

| G.W |

≈500kg |

| Capacity: |

110-130kg/h |

| Applications |

Light metals, plastics, kitchen wastes, wood, paper, etc. |

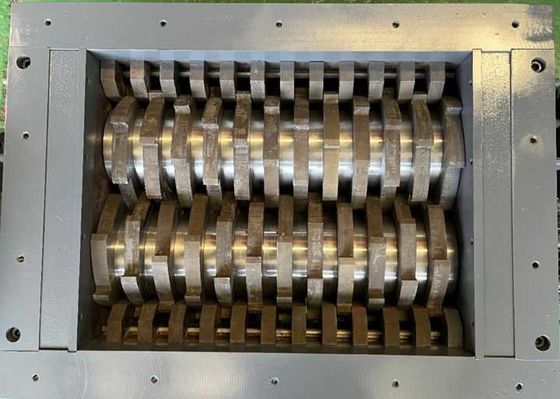

Working principle of double shaft shredder:

The working principle of the double-shaft shredder is mainly to crush and tear materials through the rotation and shearing action of the two main shafts. When the material enters the double-shaft shredder, the two main shafts rotate at different speeds, forming rotational force and shearing force, causing the material to be crushed by extrusion, shearing and friction between the two main shafts. into small pieces.

Specifically, the main shaft of a double-shaft shredder is usually made of high-strength materials, such as high manganese steel, alloy steel, etc., which have high hardness and wear resistance. When the main shaft rotates, the friction between the material and the main shaft causes the material to be torn, while the gap between the main shaft causes the material to be squeezed. At the same time, the speed difference between the two spindles also causes the material to be sheared.

In addition, the double-shaft shredder is also equipped with auxiliary devices such as blades and screens to further crush and screen materials. The blade can increase the friction between the material and the main shaft and improve the crushing effect; the screen can control the discharge granularity of the material to meet different needs.

FAQ:

Q:Could I have prices of your products?

A:Sure. Please feel free to send us an email here. You will get our reply in 24 hours

Q:How about the quality of machines?

A:Our machines adopt advanced technology. Moreover, we carry out strict supervision during productionand make sure every finished product with high quality.

Q: Do you inspect the finished products?

A:Yes, each step of production and finished products will be came out inspection by QC department before shipping.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!